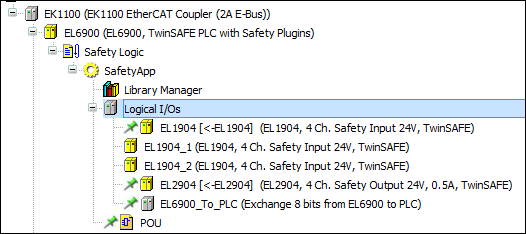

Overview of Logical I/Os

You cannot add any more hardware modules under the EtherCAT Safety Module. However, you can add safe modules and standard modules to the device tree below a coupler (e.g. EK1100). The connection to the EtherCAT Safety Module or the exchange of data with it is done by means of Logical I/Os. You can add and configure these objects under the Logical I/Os node.

For more information, see: Dialog: Properties

Principle of logical I/Os

Two types of logical I/Os are available:

Logical I/Os of safe field devices

When you add a safe field device to the device tree, a matching logical I/O is automatically inserted (same name as the I/O module) if only one EtherCAT Safety Module exists in the device tree.

In case there are multiple EtherCAT Safety Modules, you need to manually add the matching logical I/O. You need to select this logical I/O in the I/O mapping of the corresponding field device. The logical I/O contains all safety parameters of the module, so that all safety-relevant information can be found under the safety application.

Logical I/Os of global variables

These objects can be used to exchange additional data between the EtherCAT Safety Module and the standard controller. To do this, you define global variables (logical exchange GVL) in the standard project and then connect these to the corresponding logical I/O on the EtherCAT Safety Module (Logical exchange devices).

See: Logical I/O for Exchange of Data with the Main PLC (Standard Controller)

The logical I/Os of the safety application are linked with physical devices or with the Logical Exchange GVL (special object on standard side) of the standard application. This means that there is precisely one logical I/O in the safety application for each physical device whose input/output signals are processed in the safety application. Likewise, precisely one logical I/O exists under the safety application for each GVL for the logical exchange of the standard controller.

Tip

You can edit the fail-safe parameters of a device, whose inputs/outputs are processed in the safety application, only in the corresponding logical I/O in the safety application.

For a better overview, you can add folders to the project tree under Logical I/Os in order to group the logical I/Os.

Tip

By default, the logical I/Os are automatically synchronized with the assigned device objects in the device tree. As a result, the logical I/Os are inserted, renamed, or deleted when the associated fieldbus device is inserted, renamed, or deleted.

You can use the Disable Logical I/O Synchronization command to switch off this synchronization. The command is available in the context menu of the Logical I/Os object in the device tree.

Advantages of the logical I/Os

Advantages for the development and verification of a safety application with CODESYS Safety for EtherCAT Safety Module:

The safe parameters of field devices are parameterized only in the logical I/Os of the safety application. If Safety user administration has been set up, then this parameterization can be done only by members of the Safety user group.

Changed assignments of physical field devices and logical exchange GVLs do not change the safety application because the changes to assignments are made under the main application (standard application) and become effective by downloading to the main controller.

A safety application which has already been verified and accepted can be detached from the original project and fully integrated into another project without having to re-verify this new safety application. When doing this, suitable field devices and logical exchange GVLs must be reassigned to the logical I/Os of the safety application.

Notes on the logical I/Os

The logical I/Os are assigned depending on the name of the application and the logical I/O object.

Note the following:

If you change the name of a logical I/O, then the name of the physical device or the logical exchange GVL will be automatically updated. You do not need to reassign these objects to the logical I/O.

The name of the Safety application object must be unique throughout the project and the name of the logical I/O object must be unique within the safety application in order to be able to map the logical I/O object uniquely to the field device or to the logical exchange GVL.

If you rename or move a field device in the device tree or a logical exchange GVL in the main application (except for "default assignment"), then this does not change the assignment to the logical I/O in any way. This is because the safety application is automatically modified: The assigned logical I/O is renamed in the same way as the field device.

If you delete a field device in the device tree or delete the logical exchange GVL in the standard application, then the result will be that the assigned logical I/O will no longer be mapped to anything.

If you delete a logical I/O object, then the result will be that no more fail-safe settings are mapped to the field device. The variables in the safe exchange GVL (Safety variables) are also no longer connected.

If another logical I/O object is given the old name of a renamed or deleted logical I/O object, then its settings are mapped to the assigned field device from now on. The variable values for Logical Exchange GVL are linked. The assignment is thus indirectly changed.

If a logical I/O is deleted and a new logical I/O with the name of the deleted logical I/O is added, then the assignment will be active again.

The Module Fault (Fail Safe Data) is COM ERR option is located in the Connection Settings in the Properties dialog of a logical I/O device. When this option is enabled, the reception of the

FailSafeDatacommand will be handled as a communication error.For more information, see: Dialog: Properties