SMC_ToolRadiusCorr (FB)¶

FUNCTION_BLOCK SMC_ToolRadiusCorr

SMC_ToolRadiusCorr creates a shifted path to compensate for the

radius of a tool.

In the shifted path, each point has a defined distance to

the original point (tool radius correction).

A typical application is the milling of a programmed contour with a

milling drill of a certain diameter. In order to compensate the radius

of the drill, the milling drill must follow a shifted path.

This function block replaces SMC_ToolCorr.

The main feature is to also support 3d-movements

and to respect the current correction plane

(i.e. at decoding time the plane that circles would be defined in).

We always use SMC_TOOLCORRMODE.TC_RAMP_IN,

so the input eMode is no longer necessary.

Tool radius correction is controlled by the g-code:

G41 (G42) starts correction to the left (right),

G40 ends it.

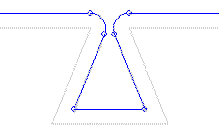

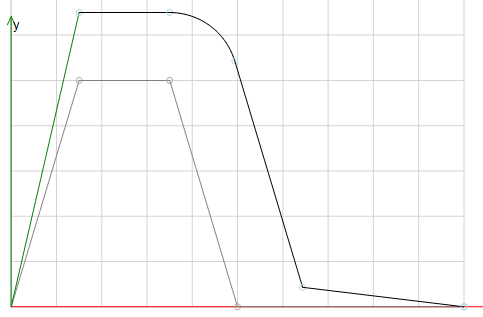

Example 1: Simple tool radius correction

G-Code

N0 G41 D3 (start correction)

N1 G0 X3 Y10 F100 E1000 E-1000

N2 G1 X7 Y10

N3 G1 X10 Y0

N4 G40 (end correction)

N5 G1 X20

In the above example, the element in sentence N1 is used for ramping in, the one in sentence N5 for ramping out.

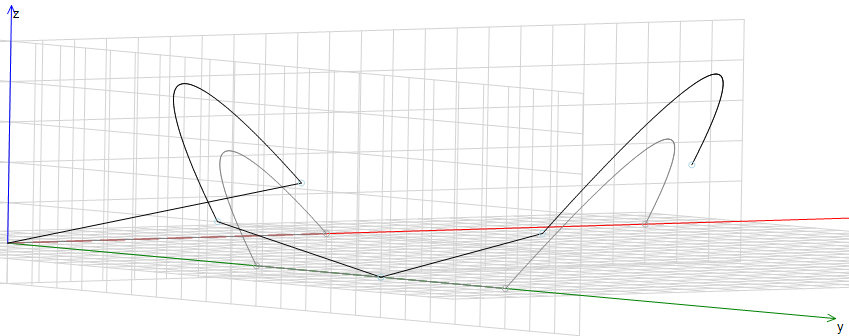

Example 2: Tool radius correction in different planes

G-Code

N0 G41 D1 F100 (start correction)

N1 G16 I1 J1 K1 (set correction plane)

N2 G1 X5

N3 G2 X0 Y5 R5

N4 G40 (turn off correction)

N5 G1 X0 Y7.5

N6 G42 D1 (start correction)

N7 G16 I1 J1 K-1 (with different correction plane)

N8 G1 Y10

N9 G3 X10 Y0 R15

This example shows how tool radius correction can work

in different planes. The correction plane is changed with G16.

The elements in sentence N5 and N8 are used for ramping out and

ramping in again.

Note

At inside corners, the projections of the corrected (shifted) elements onto the correction plane will usually intersect and we shorten those elements accordingly. Concerning the component which is perpendicular to the correction plane (z when correcting in the xy plane), the new meeting point will equal component of the original corner. The value of the additional axes at the point of intersection will also equal the value of the additional axes at the original corner.

G75 during tool radius correction is not supported: The correction of one element strongly depends on the following, which can’t be known if there is a G75 in between. A G75 must not follow a G40, either: The first movement after G40 is used for ramping out and therefore still “belongs” to the correction block. For the same reason, we get in trouble if the in-queue is full without containing a second cartesian element (e.g. only M-functions), and also return an error.

If the correction radius or the correction plane or the correction side (left or right) changes from one element to the other, we will act like at the beginning of tool correction and use the element with the new parameters for ramping in.

Changing the planes during tool correction is not supported. Jumps (G92 or implicitly by G43) during tool correction are not supported. Splines with degree 5, as created by SMC_SmoothPath or SMC_SmoothMerge, are not supported yet.

G0 elements can be used during tool radius correction. They will be shifted and cut like G1 elements.

Ellipses (G08/G09) are not supported. An error will be reported when an ellipse element is detected during active tool radius correction.

- InOut:

Scope

Name

Type

Comment

Input

bExecuteBOOLStarts on rising edge

bAbortBOOLIf

TRUE, the current processing of this function block is abortedbAppendBOOLAs long as this input remains

FALSE, the DataOutQueue will be cleared at each reset. As long as it remainsTRUE, newly incoming data will be written to the end of the DataOutQueue.poqDataInPOINTER TO SMC_OUTQUEUE

Input path queue

nSizeOutQueueUDINTThe size of pbyBufferOutQueue in bytes

pbyBufferOutQueuePOINTER TO ARRAY [0..0] OF SMC_GEOINFO

The buffer for the output queue

dAdditionalToolRadiusLREALThis variable defines an additional tool radius. Whenever a new tool radius correction starts, it is added to the tool radius defined in the SMC_GEOINFO structure. The path will then be shifted by the new tool radius. If this variable is modified during an active tool radius correction, it will have no effect until the active tool radius correction ends and a new tool radius correction is started (with

G41orG42). Note: The additional tool radius may also be negative. If the sum of the additional tool radius and the radius defined in the SMC_GEOINFO structure is negative, the correction side is inverted (left <-> right).Output

bDoneBOOLIndicates the entire input path has been processed

bBusyBOOLIndicates the function block is still busy processing

bErrorBOOLAn error has occurred

wErrorIDSMC_ERRORError-ID

poqDataOutPOINTER TO SMC_OUTQUEUE

Output path queue