ExampleHotWater (FB)¶

FUNCTION_BLOCK ExampleHotWater

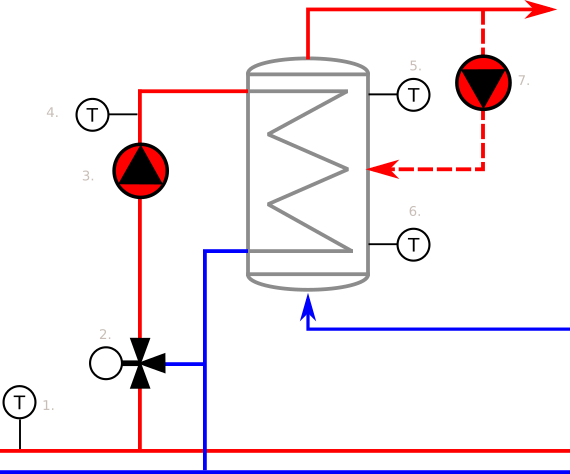

Example hot water boiler control

This example function block implements a simple hot water boiler control to demonstrate how to implement a plant / an aggregate in ST using CODESYS Building Automation library function blocks. All other examples are implemented using CFC, because this way it’s a bit more easy to read / understand. No matter of this ST is also a good choice to implement plants / aggregates. Here we demonstrate, that an implementation using ST is also easy to read / understand if structured nicely and well documented.

This example involves:

2 point control of boiler temperature

steady control of boiler supply temperature

demand-based activation of loading pump

legionella prevention

optional unload protection using supply temperature sensor

Watch out for comments in the implementation where those aspects are covered.

supply temperature sensor

mixing valve

loading pump

boiler supply temperature sensor

upper boiler temperature sensor

lower boiler temperature sensor

circulation pump

2 point control of boiler temperature¶

A boiler load cycle is requested, if boiler temperature is below setpoint. The boiler load cycle is stopped, if boiler temperature exceeds setpoint plus hysteresis.

Legionella prevention¶

Boiler temperature is to be kept above 60°C for at least an hour the day. Circulation pump is enabled during this load cycle.

Optional unload protection¶

In case there is a supply temperature sensor ExampleHotWater checks the supply temperature before / during a load operation. In case the supply temperature is below boiler temperature the boiler will not be loaded.

Caveats¶

To keep complexity as low as possible this example omits - amongst others - the following real world application aspects worth mentioning:

configuration missing (configuration of m_legionellaPreventionDone, m_legionellaPreventionTimer, m_loadPump, m_circPump, m_mixingValve etc. is not or not completely exposed on the ExampleHotWater VAR_INPUT section)

input consistency checks (rHyst <= 0, implausible measurement values, …)

no legionella warning issued, if legionella prevention load cycle is missed due to unload conditions

sensors missing (both pumps - service / error indication, …)

xError / eErrorID not computed at all, see ExampleAirConditioning2 how to do this

sensor / actuator process I/O not mapped (FB sensor inputs, m_loadPump, m_circPump, m_mixingValve, …)

- InOut:

Scope

Name

Type

Initial

Comment

Input

rSetptREAL50.0

Hot water temperature setpoint

rHystREAL5.0

Hot water temperature hysteresis

rSupplyTempREALSupply temperature

xSupplyTempSensorBOOLFALSE

Optional supply temperature sensor exists

rBoilerSupplyTempREALBoiler supply temperature

rBoilerTemp1REALUpper boiler temperature

rBoilerTemp2REALLower boiler temperature

xCircPumpRequestBOOLFALSE

Request circulation pump

tLegionellaTIMETIME#1440m0s0ms

Time to next legionella prevention boiler load cycle

xResetBOOLFALSE

Reset

itfDateTimeProviderUtil.IDateTimeProviderGlobals.g_dtpDateTimeProvider

Source for the current date and time information in milliseconds since 1.1.1970 00:00:00.000

Output

rRequestedBoilerTempREALRequested boiler temperature

xLegionellaPreventionDoneBOOLLegionella prevention has been done in the last 24 hours

xLoadBOOLBoiler will be loaded actually.

xLoadPumpBOOLLoading pump running

xCircPumpBOOLCirculation pump running

rValveREALMixing valve

tLegionellaRemainingTIMERemaing time to next legionella prevention boiler load cycle