SF_EmergencyStop

Tip

The version of the function block as described here corresponds to the latest version of the function block in Version list of function blocks.

Applicable safety standards

SF_EmergencyStop is a certified PLCopen function block. For detailed information about applied standards, see "PLCopen – Technical Committee 5 – Safety Software".

Important

The requirements listed in the standards must be fulfilled by the user.

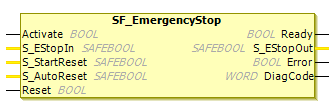

Interface description

This function block is a safety-oriented function block for monitoring an emergency stop button. SF_EmergencyStop can be used for emergency switch-off functionality (stop category 0), or – with additional peripheral support – as emergency stop (stop category 1 or 2).

Name | Data Type | Initial Value | Description, parameter values |

|---|---|---|---|

|

|

| |

|

|

| Input which requests safety Variable

|

|

|

| |

|

|

| |

|

|

|

Name | Data Type | Initial Value | Description, parameter values |

|---|---|---|---|

|

|

| |

|

|

| Output for safety-oriented response

Request for safety-oriented response (for example, emergency stop button is engaged, reset required or internal error exists)

No demand for safety-oriented response (e.g. emergency stop button not engaged; no internal errors active). |

|

|

| |

|

|

|

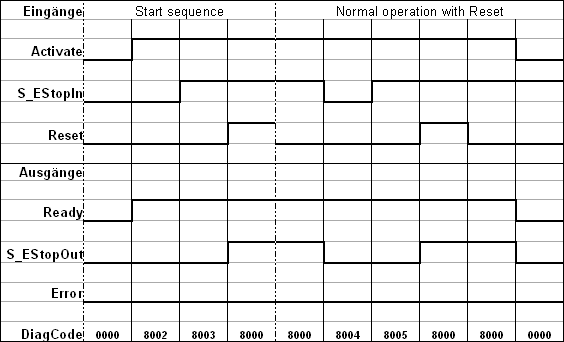

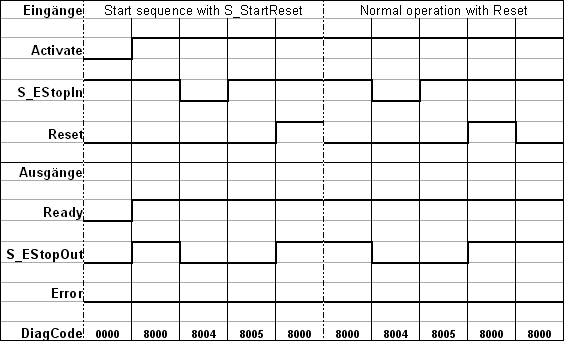

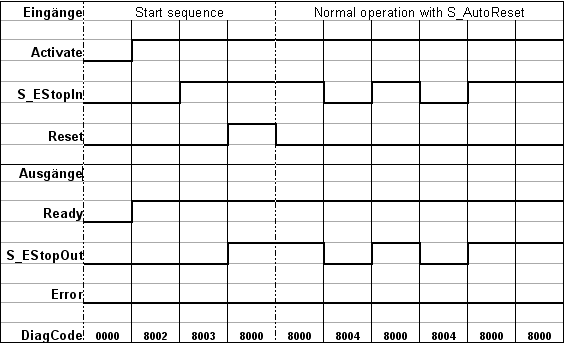

Functional description

The S_EStopOut enable signal is reset to FALSE as soon as the S_EStopIn input is set to FALSE. The S_EStopOut enable signal is reset to TRUE only if the S_EStopIn input is set to TRUE and a reset occurs. The enable reset depends on the defined S_StartReset, S_AutoReset, and Reset.

If S_AutoReset = TRUE: Acknowledgment is automatic.

If S_AutoReset = FALSE: A rising trigger at the Reset input must be used to acknowledge the enable.

If S_StartReset = TRUE: Acknowledgment is automatic the fist time the S-PLC is started.

If S_StartReset = FALSE: A rising trigger at the Reset input must be used to acknowledge the enable.

Caution

The S_StartReset and S_AutoReset inputs shall only be activated if it is ensured that no hazardous situation can occur when the S-PLC is started.

SF_EmergencyStop can be used to monitor both single and dual-channel emergency stop buttons. For example, for two-channel applications, the additional SF_Equivalent function block can be used to detect whether the contact synchronization has been exceeded. The category classification in accordance with EN ISO 13849-1 will depend on the final elements that are used.

The SF_EmergencyStop automatically detects a static TRUE on Reset. Further error detection, e.g. wire break or short circuiting, depends on the dedicated hardware that is used.

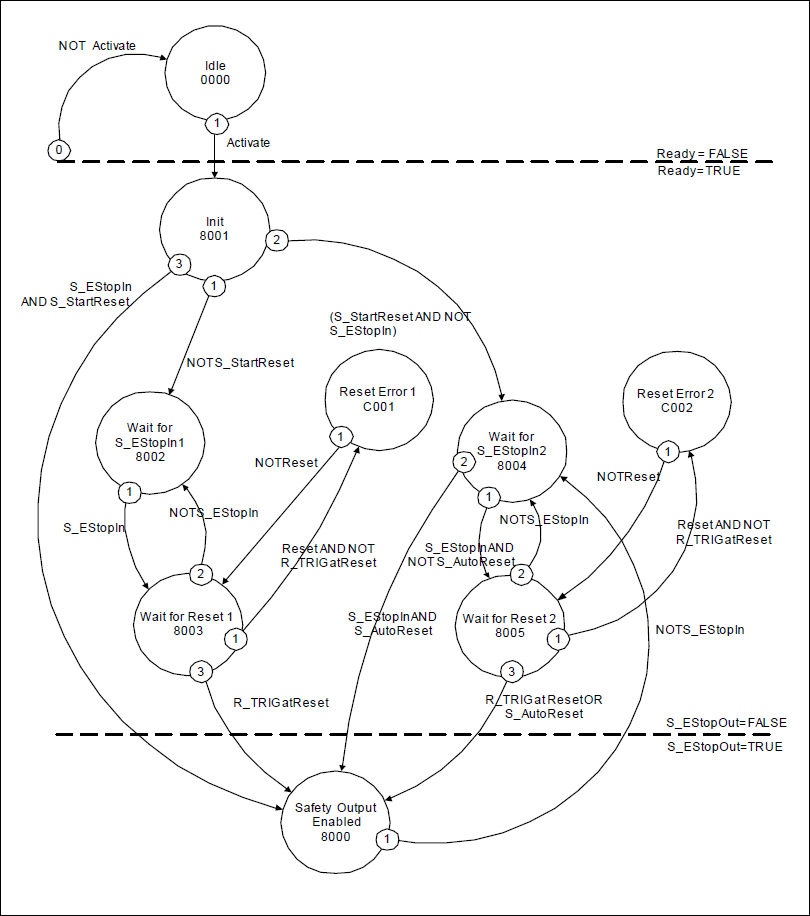

Status diagram

Tip

Note: The transition from any state to the Idle state, initiated by Activate = FALSE, is not shown. In every case, these transitions have the highest priority.

Error detection

The POU detects a static TRUE signal at the Reset input.

Error behavior

S_EStopOut is set to FALSE. In case of a static TRUE signal at the Reset input, the DiagCode output shows the relevant error code and the Error output is set to TRUE.

To exit the error states, the reset has to be set to FALSE.

FB-specific error and status codes

| Statue Name | Status description and output setting |

|---|---|---|

|

| While waiting for

|

|

| While waiting for

|

| Statue Name | Status description and output setting |

|---|---|---|

|

| The function block is not active (basic state).

|

|

| Activation is TRUE. The block has been activated. Check whether

|

|

| Activation is

|

|

| Activation is

|

|

| Activation is

|

|

| Activation is

|

|

| Activation is

|