Overview of Compound Safety PLC

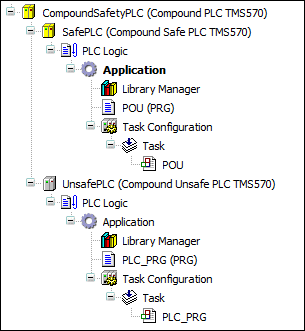

CODESYS Safety SIL2 extends the CODESYS programming system with the functionality "Compound Safety PLC". A Compound Safety PLC comprises a safety application and a standard application, which can be run in parallel.

The Compound Safety PLC basically differs from a conventional Safety SIL2 PLC in the following aspects:

Structuring: SIL2 controller and one or more standard PLCs below a logical parent PLC

Handling of Compound Safety PLCs in CODESYS projects differs from the handling of standard PLCs (first steps to create a new project / scan PLC, etc.)

For more information, see: Handling of the Compound Safety PLC

Handling of EVC/EVL with a Compound Safety PLC

For more information about Exchange Variable Connection, see: EVC, Exchange Variable Connection

For more information about Exchange Variable List, see: EVL, Exchange Variable List

Synchronization of the tasks of the safety application and the standard application

If the tasks of the safety application and the standard application have to be processed synchronously, then they can be synchronized by means of events. There are two options for this:

If the manufacturer of the controller offers external events for the standard application which can be synchronized with the tasks of the safety application, then the tasks of the standard application can be defined as "External Event Tasks". This makes the time behavior deterministic.

Independent of this, simple "Event Tasks" can also be used in the standard application which use event variables of the safety application, which are provided via the EVC. Because an "Event Task" does not start immediately after the event is set, the timing behavior is not deterministic.