Handling of the Compound Safety PLC

Because the Compound Safety PLC consists of a structured relationship between multiple Safety controllers and standard controllers, a special handling for some standard use cases is required:

First steps to create a new project

Device update

Device scan / communication with the PLCs

Tip

Check also the OEM documentation from the device manufacturer for notes about special handling or requirements of the Compound Safety PLC of the particular manufacturer.

First steps to create a new project

The default CODESYS wizard for creating a standard project does not support the automatic creation of a Compound Safety PLC CODESYS project. Therefore, the first steps are as follows:

Create an empty CODESYS project.

In the Devices view, add a new device: Right-click the root node and click Add Device in the context menu.

In the Add Device dialog, select the correct device for the Compound Safety PLC and click Add Device to confirm.

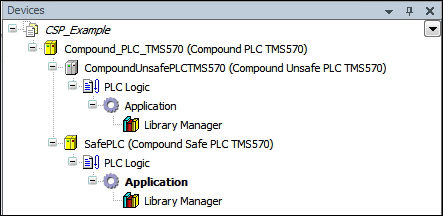

The Compound Safety PLC is displayed in the Devices view, for example:

Device update

The Compound Safety PLC can consist of multiple devices (see the figure above). Therefore, if you want to update all parts of the Compound Safety PLC, then use the Update Device command on each of the affected devices. See the recommended steps as follows:

Install all device descriptions provided by the OEM that you want to update and that are part of the Compound Safety PLC.

Update the device of the root PLC.

Update all devices below the root PLC.

Device scan / communication

In the default Compound Safety PLC, the handling for device scan and communication differs slightly from that of a standard PLC.

Device scan for a Compound Safety PLC

The Compound Safety PLC has one root PLC, and only this PLC is able and responsible for performing the device scan. To scan the Compound Safety PLC, use the Communication Settings of the root PLC (similar to a standard CODESYS PLC).

NOTE: In the subdevices, there is no Communication Settings tab.

If the device scan was successful and an "active path" is set for the root PLC, then you see a message in the Messages view which confirms that the communication settings for the subdevices have been automatically set in the background.

Connecting to the PLC

The subdevices of a Compound Safety PLC are independent PLCs, except with regard to the communication settings or the EVLs or EVCs.

This means that online services such as "application download", "start application", "enter debug mode" and so on are specific to the selected subdevice (by the "active application").

Example: An application download to subdevice A is handled only by subdevice A and so on. The application of subdevice B is unaffected by this.