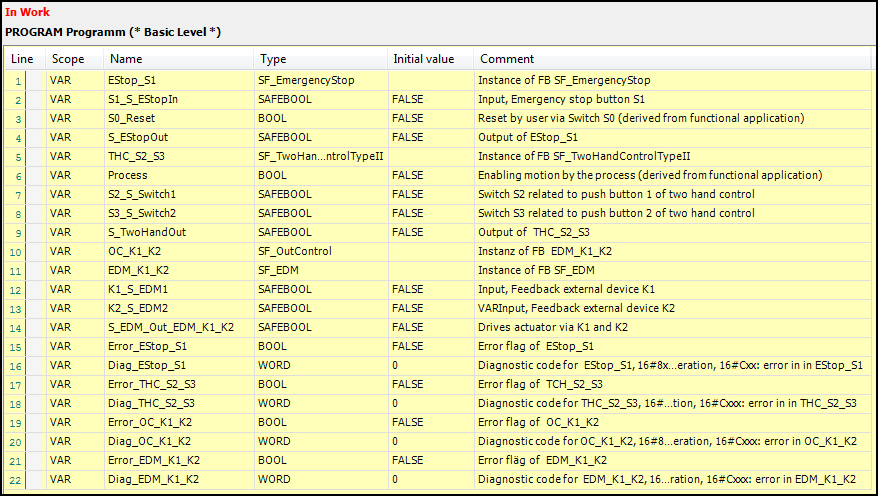

Programming example for Basic Level

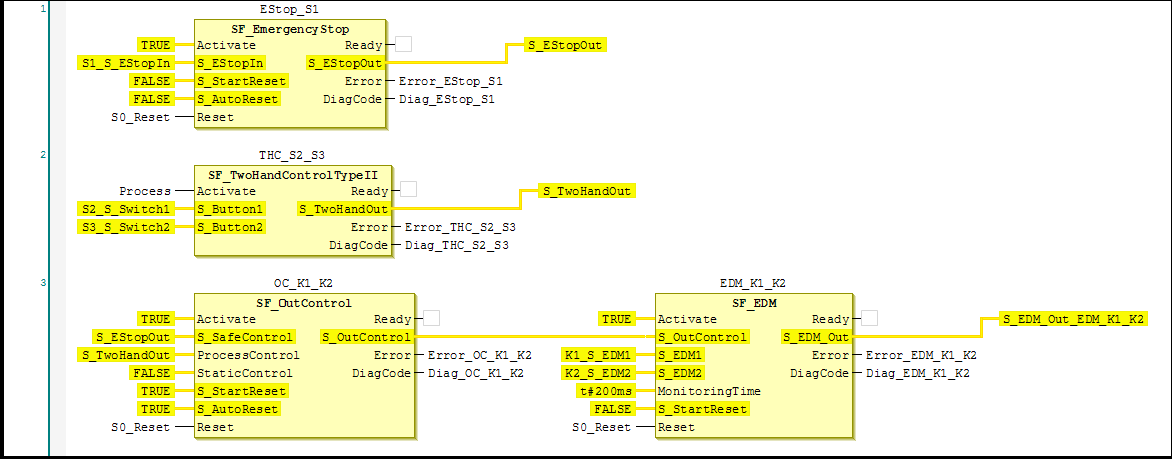

The example "Two-hand control with EDM" from the document "PLCopen – Technical Committee 5 Safety Software Technical Specification Part 2: User Examples Version 1.01 – Official Release" is used as a CODESYS Safety Extension programming example for a program in the Basic Level and illustrated as a CODESYS Safety Extension FBD implementation.

Tip

For more information about programming in the Basic Level, see the document "PLCopen - Technical Committee 5 Safety Software".

Functional description of the safety functions

The following safety functions are used in this example:

When the emergency stop button is pressed, all dangerous movements must be stopped (via

SF_EmergencyStop)Emergency stop has the highest priority. After releasing the

EStoppushbutton, a reset via S0 reset is required.The safety output is activated by pressing both pushbuttons of the two-hand control. Releasing any of the two-hand pushbuttons deactivates the safety output and stops the hazardous movement via the switching devices

K1andK2(viaSF_TwoHandControlTypeII)The basic state and the operating state of the connected switching devices are monitored. If an error is detected, then the safety output cannot become operational. (via

SF_EDM)After switching on the safety or functional application, or after an emergency stop condition, the two-hand control has to be released and actuated again to reactivate the safety output (via

SF_OutControl). To ensure this for the functional restart, the process signal of the functional application is connected to theActivateinput of the two-hand control FBTHC_S2_S3. (If the application process is restarted while the two-hand control is activated, then the device goes to statusC0003, which signals the error that both pushbuttons are pressed when activated and prevents a restart.)

In this example, only one operating state exists.

Name | Data Type | Description |

|---|---|---|

|

| Emergency stop button S1 |

|

| Switch S2 connected with pushbutton 1 of two-hand control |

|

| Switch S3 connected with pushbutton 2 of two-hand control |

|

| Feedback external device K1 |

|

| Feedback external device K2 |

|

| Reset by developer with switch S0 (derived from functional application) |

|

| Release of the movement by the process (derived from the functional application) |

Name | Data Type | Description |

|---|---|---|

|

| Controls the actuator via |

|

| Error flag of |

|

| Error flag of |

|

| Error flag of |

|

| Diagnostic code for

|

|

| Diagnostic code for

|

|

| Diagnostic code for

|

Additional notes

This example can also be used with SF_TwoHandControlTypeIII.

The input of Activate was set to TRUE for the sake of simplicity. This can be replaced by a variable in the application.

Function Block | Input | Constant Value | Description |

|---|---|---|---|

|

|

| No automatic reset when the S-PLC is started. |

|

| No automatic reset, reset/confirmation by developer necessary | |

|

|

| Automatic reset is allowed when the S-PLC is started. |

|

| Automatic reset, no reset/confirmation by developer necessary | |

|

| A dynamic change of the Appl_Control signal (rising edge) is requested after function block activation or a triggered safety function ( | |

|

|

| No automatic reset when the S-PLC is started. |

|

| The maximum response time of the two feedback signals

|