PID (FB)¶

FUNCTION_BLOCK PID

Represents a PID controller

Bemerkung

The PID controller itself measures the elapsed time between two calls, however with a maximum accuracy of milliseconds. This

might lead to rough running in case of short cycle times: For example in case of a cycle time of 1ms the PID sometimes might

measure 2 ms, sometimes 0 ms. So if possible, for such cases better use PID_FIXCYCLE, where the cycle time can be set precisely.

See PID_FIXCYCLE

Bemerkung

Consider that the controller parameters only get applied when used in the manual mode at a start, a reset or at a change down.

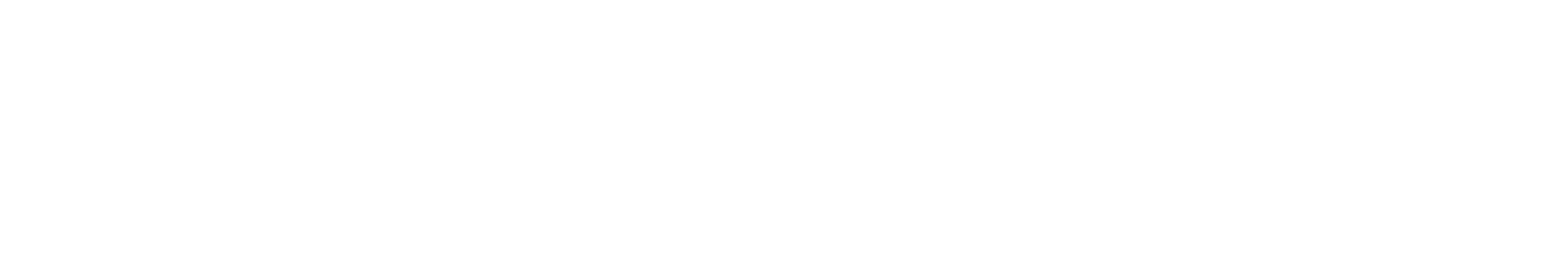

A PID controller continuously calculates an error value e(t) as the difference between a desired set point and a measured process variable. The PID controller applies a correction based on proportional, integral, and derivative terms (sometimes denoted P, I, and D respectively) which give their name to the controller type.

P accounts for present values of the error. For example, if the error is large and positive, the control output will also be large and positive.

I accounts for past values of the error. For example, if the current output is not sufficiently strong, the integral of the error will accumulate over time, and the controller will respond by applying a stronger action.

D accounts for possible future trends of the error, based on its current rate of change.[1]

As a PID controller relies only on the measured process variable, not on knowledge of the underlying process, it is broadly applicable. By tuning the three parameters of the model, a PID controller can deal with specific process requirements. The response of the controller can be described in terms of its responsiveness to an error, of the degree to which the system overshoots a setpoint, and of the degree of any system oscillation. The use of the PID algorithm does not guarantee optimal control of the system or even its stability.

Y_OFFSET, Y_MIN and Y_MAX serve for transformation of the manipulated variable within a prescribed range.

MANUAL can be used to switch to manual operation; RESET can be used to re-initialize the controller.

In normal operation (MANUAL = RESET = LIMITS_ACTIVE = FALSE) the controller calculates the controller error e as difference from SET_POINT –

ACTUAL, generates the derivation with respect to time \(\frac{\delta e}{\delta t}\) and stores these values internally.

The output Y is the manipulated variable unlike the PD controller contains an additional integral part,

and is calculated as follows: \(Y = KP \cdot (e + \frac{1}{TN} \int e dt + TV \frac{\delta e}{\delta t}) + Y_{OFFSET}\)

So besides the P-part also the current change of the controller error (D-part) and the history of the controller error (I-part) influence the manipulated

variable. The PID controller can be easily converted to a PI-controller by setting TV=0.

Because of the additional integral part, an overflow can come about by incorrect parameterization of the controller, if the integral of the error e becomes

to great. Therefore for the sake of safety a BOOLean output called OVERFLOW is present, which in this case would have the value TRUE. This only

will happen if the control system is instable due to incorrect parameterization. At the same time, the controller will be suspended and will only be

activated again by re-initialization.

Bemerkung

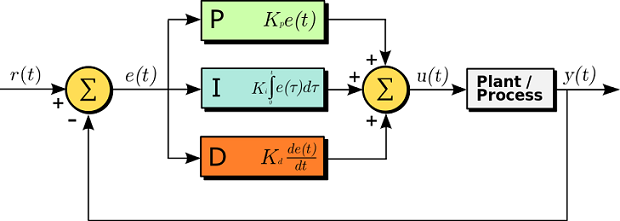

As long as the limitation for the manipulated variable (Y_MIN, Y_MAX) is active, the integral part will be adapted, like if the history

of the input values had automatically effected the limited output value. If this behaviour is not wanted, the following workaround is

possible: Switch off the limitation at the PID controller (Y_MIN>=Y_MAX) and instead apply the LIMIT operator (IEC standard) on

output value Y (see an example in the figure below).

Bemerkung

It is not necessary to readjust the controller parameters (KP, TN, TV) if the cycle time changes.

Temperature control with PID and LIMIT¶

See in the following figure a simple example of using the PID module for temperature control and in combination with the LIMIT operator. The input of

the actual temperature is simulated by giving a constant value via ActualTemperature.

- InOut:

Scope

Name

Type

Initial

Comment

Input

ACTUALREALCurrent value, process variable

SET_POINTREALDesired value, set point

KPREALProportionality const. P

TNREALReset time I [sec]

TVREALRate time, derivative time D [sec]. If set to 0, then it works as PI controller

Y_MANUALREALYis set to this value as long asMANUAL=TRUEY_OFFSETREALOffset for manipulated variable

Y_MINREALMinimum value for manipulated variable

Y_MAXREALMaximum value for manipulated variable

MANUALBOOLTRUE: Manual:Yis not influenced by controllerFALSE: Controller determinesYRESETBOOLTRUE: SetYoutput toY_OFFSETand reset integral partOutput

YREALManipulated variable, set value

LIMITS_ACTIVEBOOLFALSE

TRUE:Yhas exceeded the given limitsY_MIN,Y_MAXand is limited to these valuesOVERFLOWBOOLFALSE

Overflow in integral part