Kin_5Axes (FB)¶

FUNCTION_BLOCK Kin_5Axes EXTENDS Kin_Coupled

Transformation FB for 5-axes-gantries. This is a possible way how a coupled kinematic can be realized based on existing kinematics.

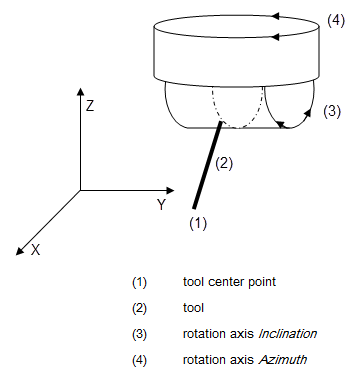

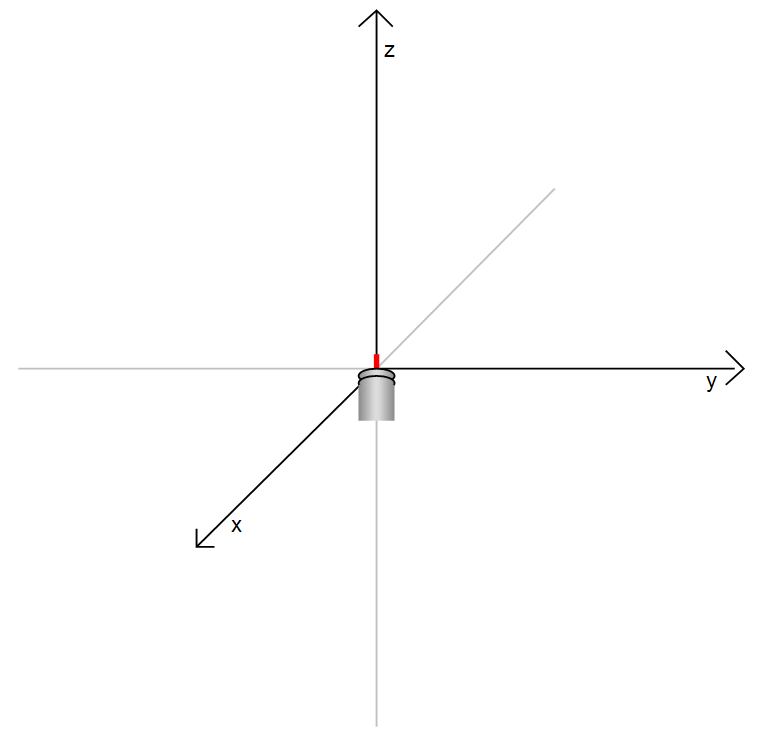

The 5-axes transformation enables the controlling of 3 linear axes (X, Y, Z) carrying a tool head, which consists of two axes carrying the tool. The tool head can be turned around the Z-axis and can be tilt according to the scheme aside.

Machine coordinate system (MCS) |

|

|---|---|

Origin |

The location of the TCP when the first three axes are 0. |

X |

Corresponds directly to the direction of the first axis (a0), i.e. a positive velocity on the first axis leads to a movement in positive x direction in the MCS. |

Y |

Corresponds directly to the direction of the second axis (a1), i.e. a positive velocity on the second axis leads to a movement in positive y direction in the MCS. |

Z |

Corresponds directly to the position of the third axis (a2), i.e. a positive velocity on the third axis leads to a movement in positive z direction in the MCS. |

The location of the tool coordinate system (TCS) relative to the MCS in zero position:

Tool coordinate system (TCS) |

|

|---|---|

Origin |

Relative to MCS: dX = 0 dY = 0 dZ = dToolLength |

X |

Along the X-Axis of the MCS in positive direction |

Y |

Along the Y-Axis of the MCS in positive direction |

Z |

Along the Z-Axis of the MCS in positive direction |

In zero position, the tool center point (TCP) is located on (0, 0, dToolLength), the tool extends in the direction of the Z axis. Moving the Inclination axis in positive direction moves the tool in the direction of the positive X axis (if dToolLength <> 0).

The single axes values have the following interpretation:

a0 |

position of the x axis of the machine (X) |

a1 |

position of the y axis of the machine (Y) |

a2 |

position of the z axis of the machine (Z) |

a3 |

angle [deg] of the yaw axis (azimuth) (A) |

a4 |

angle [deg] of the roll axis (inclination) (B) |

- Attributes:

sm_kin_libdoc- InOut:

Scope

Name

Type

Comment

Inherited from

Input

itfPosKinitfOriKindToolLengthLREALLength of tool measured from the TCP to the point of intersection between the two axes (yaw/roll).

Properties:

NumAxes, inherited from Kin_Coupled

Methods:

ActivateAutomaticRotaryPeriods, inherited from Kin_Coupled

AxesToCartesian, inherited from Kin_Coupled

AxisSettings, inherited from Kin_Coupled

CPConnectible, inherited from Kin_Coupled

CartesianToAxes, inherited from Kin_Coupled

GetAxisMapping, inherited from Kin_Coupled

GetAxisMapping2, inherited from Kin_Coupled

GetAxisProperties, inherited from Kin_Coupled

GetConfigurationDataSize, inherited from Kin_Coupled

GetDefaultConfigurationData, inherited from Kin_Coupled

GetFlangeOrientationImageTotal, inherited from Kin_Coupled

GetFlangeOrientationImageWithOri, inherited from Kin_Coupled

GetPeriods, inherited from Kin_Coupled

GetPosAndToolKinematics, inherited from Kin_Coupled

IsConfigSingular, inherited from Kin_Coupled

IsInitialized, inherited from Kin_Coupled

IsSingularity, inherited from Kin_Coupled

JoinAxes, inherited from Kin_Coupled

JoinConfig, inherited from Kin_Coupled

SplitAxes, inherited from Kin_Coupled

SplitConfig, inherited from Kin_Coupled

Structure: